We are

Assembly Automation Integrator for Maximum Productivity

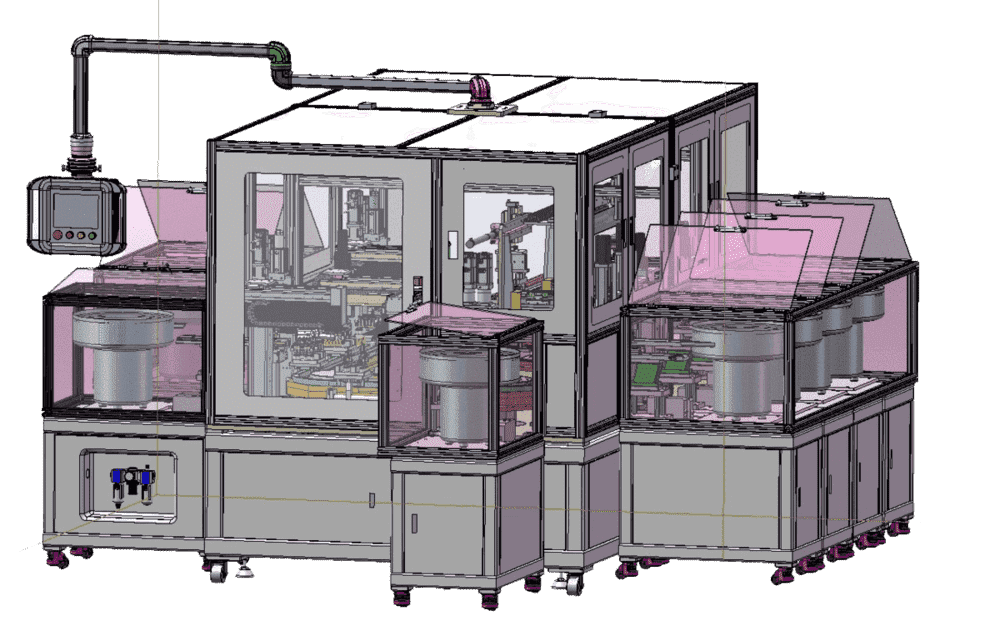

Transform Your Manufacturing with Our Customizable Automated Assembly Solutions

Our Mission

Becoming the Best Assembly Automation Provider with World-Leading Potential.

Core Competencies

Partiger specializes in providing custom and special machines to automate production and provide unsurpassed cost savings when compared to manual labor. Over the years, our team has engineered and built hundreds of machines to produce a wide variety of products. We look at each project individually and develop a unique blend of our proprietary processes and equipment to ensure all manufacturing requirements and specifications are met.

Custom Assembly

Customized assembly automation refers to the development and implementation of automated systems that are tailored to specific requirements and specifications of a particular business or industry.

Hardware assembly

Hardware assembly non-standard automation refers to the use of automation technology to realize the production of non-standard hardware products.

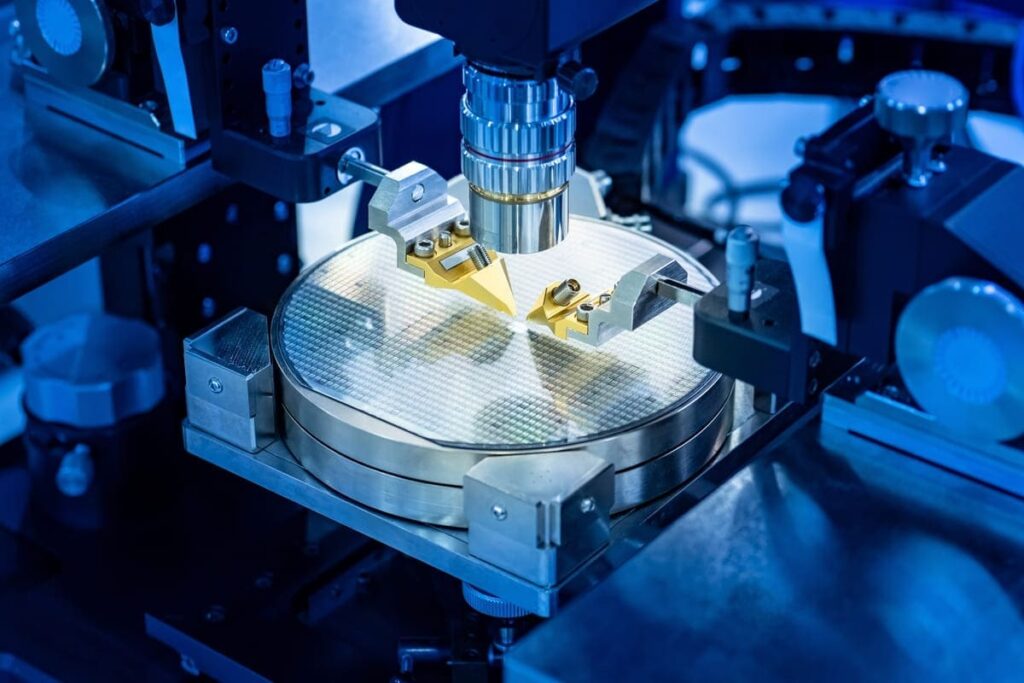

Electronics

Electric power electronics automation refers to the use of automated systems to design, test, and manufacture custom power electronics products for specific applications.

Automotive

We get creative, often combining multiple platforms to fulfill the requirements of each project.

Robotics

Partiger is a quality supplier of integrated assembly robotic automation systems for customer.

Consumer Products

Our team of experienced engineers fabricates all types of custom assembly automation solutions and equipment.

Partiger Industry Application Range

At Partiger, we pride ourselves on our innovative approach to manufacturing processes. Our automated systems offer creative solutions that are designed to stand the test of time. manufacturing processes.

With over 10 years of experience, we have built more than 150 high-speed, automated assembly machines. Our expertise allows us to design systems that can handle even the most complex manufacturing needs.

One of our unique strengths is our ability to efficiently feed a variety of components into a centralized machine and combine them seamlessly. Whether your product has only a few components or more than 15, our systems ensure precise and efficient assembly.

We customize our solutions to your specific application, integrating the best available equipment, software, and technology. Our systems are highly efficient and reliable, with proven results that increase manufacturing speed, productivity, and profitability. solutions to your specific application, integrating the best available equipment, software, and technology.

Advantages of assembly automation

Assembly equipment can improve efficiency, quality, flexibility, cost savings, and safety in the manufacturing process.

Increased efficiency

Assembly equipment can automate the assembly process, increasing the speed and efficiency of production.

Improved quality

Automation reduces the risk of human error, resulting in consistently high-quality products

Cost savings

Assembly equipment can reduce labor costs and increase productivity, resulting in cost savings for the manufacturer.

Flexibility

Assembly equipment can be easily reconfigured to accommodate different products or production processes, making it a versatile solution for manufacturers.

Cooperation Process

Let us help you solve your assembly integration problems !

We build the best Custom Automation Solutions to improve your manufacturing process.

FAQs

Let's Crack Those Questions

Our standard lead time is 4~6 weeks. However, this can vary depending on the complexity and customization of the equipment.

Our equipment is custom-built for each client, so the price can vary depending on their specific requirements. We can provide a quote once we understand their needs.custom-built for each client, so the price can vary depending on their specific requirements. We can provide a quote once we understand their.

We offer a standard warranty of 1 years, which covers any defects or malfunctions caused by our equipment.

We have a rigorous quality control process that includes testing and inspection at every stage of production. We also use high-quality materials and components.

Yes, we offer installation and training services to ensure that our clients can use our equipment safely and effectively.

Yes, we specialize in building custom equipment to meet the unique needs of our clients. We can work with them to design and build equipment that meets their exact specifications.

Our equipment is built to last, and its expected lifespan can vary depending on usage and maintenance. We can provide guidance on how to maintain and care for the equipment to ensure maximum longevity.

We keep a stock of common replacement parts on hand, and we can typically ship them within X days. For less common parts, the lead time may be longer.

Yes, we can provide references and case studies of similar projects we have completed in the past. This can give clients an idea of our capabilities and expertise.

Let Us Help You to Find a Solution

Ready For Your Career To Take Shape?

Head Office Address

Room 706, Building 1, Hi-Tech Park, Guangqiao Road, Tianliao Community, Yutang Street, Guangming District, Shenzhen, China.

Email Address

szjw980521@gmail.com

Office Telephone & WhatsApp

+86 136 3298 0521